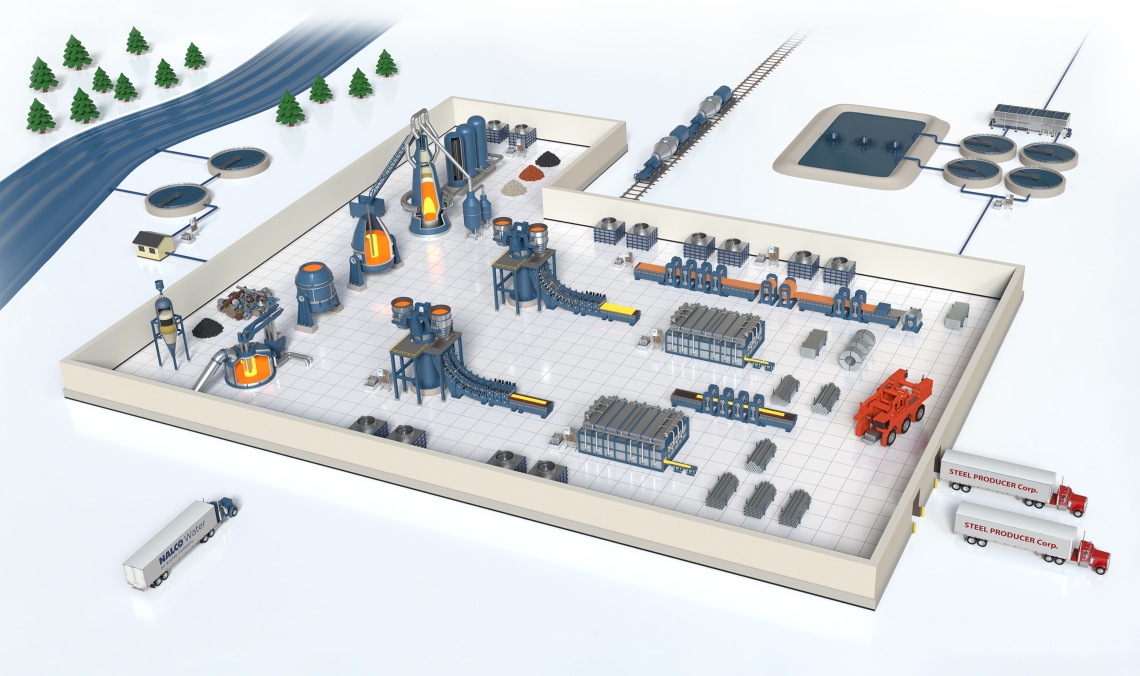

Steel Mill

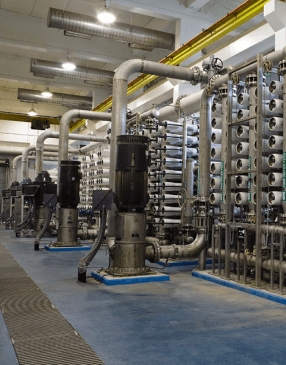

Pre-treatment

closeFrom primary clarification to sophisticated reverse osmosis monitoring and control technology, the 3D TRASAR™ Technology for Membranes program delivers performance and reliability of pre-treatment systems to meet desired water quality targets for use in process.

- 3D TRASAR Technology for Membranes — Connected chemistry for membranes including specialized cleaners, antiscalants and microbiological control offerings

- PARETO™ Mixing Technology — Efficient use and delivery of pre-treatment chemical programs

- Coagulants and flocculant for raw and make-up water clarification

- FLOCMASTER™ Technology for sludge thickening and optimization

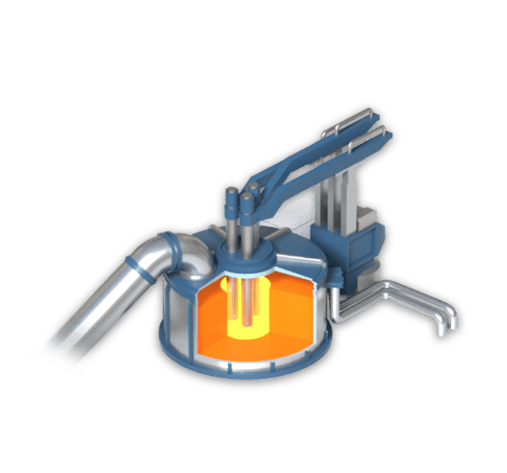

Mini Mill — Electric Arc Furnace

closeReliable and consistent operations of the electric arc furnace (EAF) are critical to meet downstream demand and cost targets. Areas of concern include mixed metallurgy, fouling, corrosion and scaling due to high heat flux and cyclical operations.

3D TRASAR™ Technology solutions are applicable for both AC and DC furnaces.

- 3D TRASAR Technology for Cooling Water — Increase in asset life of roof panels, side panels, off-gas elbow, fume ducts, etc.

- 3D TRASAR Technology — Extend electrode arm and cable and transformer life

- 3DT397™ — Halogen-resistant yellow metal corrosion inhibitor

- Monitor corrosion rates of roof panels and other critical equipment in real time

- TRAC® programs — Protect aluminum components with proprietary closed-loop programs

Integrated Mill — Blast Furnace and Coke Plant

closeCoke plant challenges include management of Coke Oven Gas (COG) systems both for the blast furnace and by-product operations to ensure maximum yield and clean gas availability for downstream operations. Blast furnace productivity depends on the quality of coke and uptime of other unit operations such as the scrubber and associated equipment.

Nalco Water connected chemistry along with 3D TRASAR™ Technology for closed-loop and open systems deliver maximum performance for ironmaking operations.

- COG treatment — Reduce fouling and deposition, and maximize utilization

- Reduce maintenance costs related to furnace downtime

- Improve furnace gas quality and scrubber reliability impacted by solids

- Achieve high level of hot metal quality

- 3D TRASAR Technology for Boilers — Maximize uptime for steam-generating assets

- PARETO™Mixing Technology for Gas cleaning circuits — Reduce downtime due to scaling and deposition

-

FLOCMASTER™

- — Optimize dewatering operations and improve sludge management material handling

- — Improve process operations with flowability aids, moisture control

- Ensure environmental compliance utilizing chemistry and digital technologies

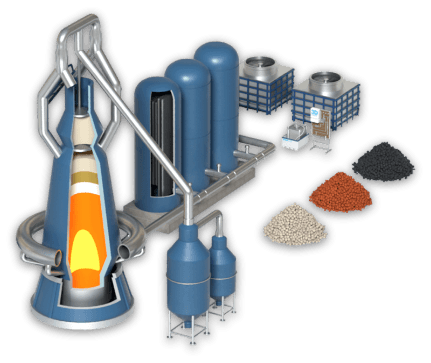

Reduced Iron

Direct Reduced Iron

closeNalco Water offers effective solutions to manage critical unit operations such as the process gas scrubber, cooling gas scrubber, dust scrubbers, clarifier and machine cooling system. Connected chemistry along with 3D TRASAR™ Technology delivers the desired outcomes by exceeding operating specifications for a DRI plant.

-

- PARETO™ Mixing Technology

— Reduce maintenance and extend run time of top gas and cooling gas scrubbers - — Reduce TSS by efficient clarifier management

- PARETO™ Mixing Technology

- FIREDUST™ Technology — Enhance safety and environmental compliance by minimizing dust and metallization loss

- 3D TRASAR Technology for Boilers — Improve reliability of steam-generating assets

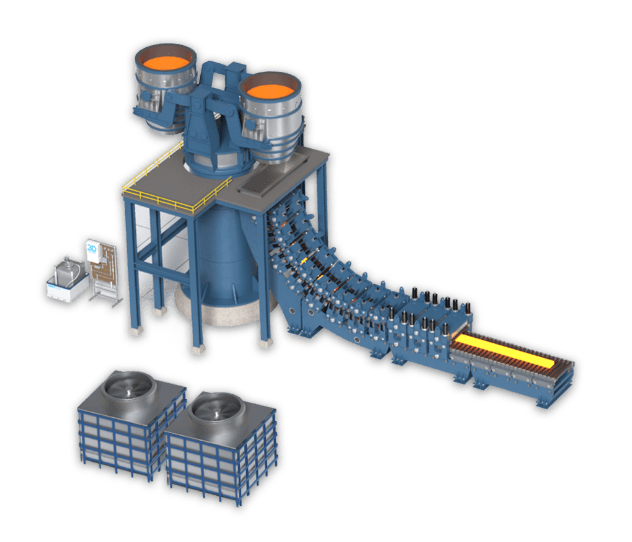

Casting

Continuous Casting

closeWater quality in the primary (closed loop) and secondary (contact) cooling systems not only affects the final product quality but also reliable caster and supporting operations. Our proprietary solutions improve asset life, improve product quality and reduce overall casting process costs.

- 3D TRASAR™ Technology — Improve asset life by controlling scale, corrosion and fouling

- CAST CLEAN™ — Extend mold life and reduce deposits in primary cooling systems

- PURATE™ — Extend asset life with reduction of halides usage and reduce biofouling with reliable, on-site generation of chlorine dioxide

- SPRAYSURE™ — Drive operational efficiency of the entire secondary cooling process with effective solids and oil removal to deliver maximum cooling water performance for contact systems

- Low-P and non-P offerings — Deliver maximum corrosion protection and compliance with environmental regulations

- 3D TRASAR Caster Technology — Reduce spray chamber corrosion, extend segment life

- Electromagnetic stirring protection — Protect systems with specially designed low-conductivity programs

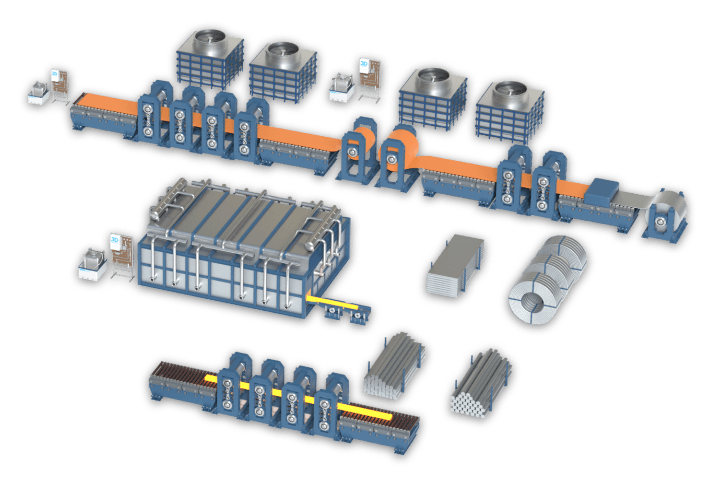

Finishing

Rolling and Finishing

closeReliable operation of the reheat furnace systems, roughing stands, descaling system finishing mill and laminar system is critical to avoid downtime related to product defects and equipment failure.

- 3D TRASAR™ Technology — Improve asset life by controlling scale, corrosion and fouling

- IronGuard™ — Improve oil and mill scale separation for reuse as iron units, thereby reducing overall costs

- PURATE™ — Extend asset life and reduce biofouling with reliable, on-site generation of chlorine dioxide

- SPRAYSURE™ — Drive operational efficiency of the entire secondary cooling process with effective solids and oil removal to deliver maximum cooling water performance for contact systems

- Low-P and non-P offerings — Deliver maximum corrosion protection and compliance with environmental regulations

- PARETO™ Mixing Technology — Maximize system performance with uniform additive distribution in a shorter time compared to traditional injection systems

- 3D TRASAR Technology for Dissolved Air Flotation — Improve solid-liquid separation process with consistent performance and real-time visibility

- FLOCMASTER™ — Optimize dewatering operations and improve sludge management

Solutions

Digital Solutions

close

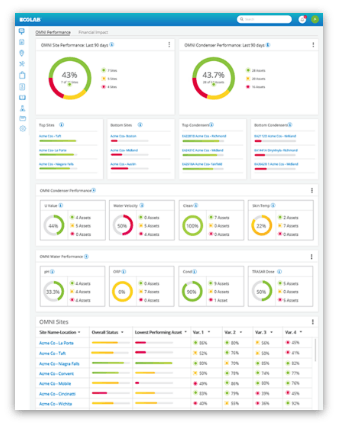

Nalco Water’s digital technologies include automation, connected chemistry and data analytics that provide actionable insights into the process to mitigate and ultimately correct upsets to deliver desired outcomes.

- ECOLAB3D™ platform — Improve operational efficiency and reduce environmental impact with a cloud-based digital platform that translates data insights into meaningful actions

- Tank level automation — Ensure product availability and inventory management with real-time connectivity

- System Assurance Center — Immediate response with suggested actions and root causes to prevent future upsets with 24/7/365 monitoring of systems

- 3D TRASAR™ Technology with connected chemistry

- E-Data capability — Allows data capture from various sources into one platform for correlation and connection with key process parameters

and Sustainability

Total Water Management and Sustainability

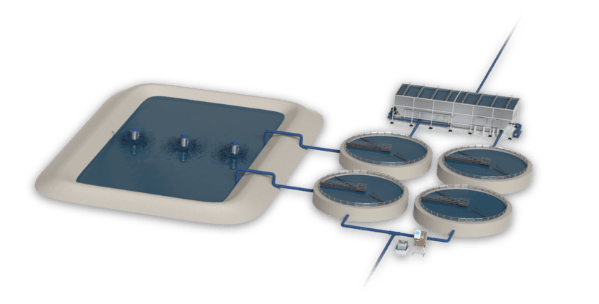

closeA solution-focused, fully integrated offering through an unmatched combination of on-site expertise, digital technologies, connected chemistry and managed operations.

- Engineering approach to identify opportunities to reduce, recycle and reuse water

- Deliver guaranteed ROI based on agreed upon performance and sustainability targets

- Services to manage critical water systems at your facilities to reliably deliver the water quality needed for processes and meet environmental compliance

- Talent to operate water treatment unit operations at your facilities to deliver the water quality needed to operate your processes reliably

- Water Efficiency Plan — Model current and future scenarios of current water and energy balance with multiple scenario evaluation for both site expansion and sustainability targets. Detailed project plan with ROI analysis

Let us focus on water to enable you to focus on your process!

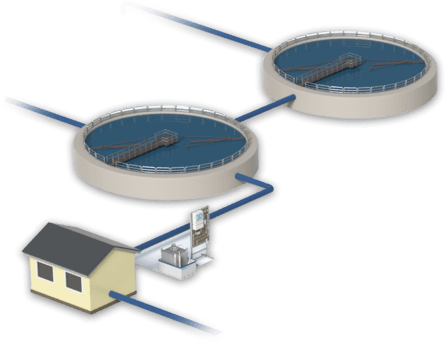

Post-treatment

close

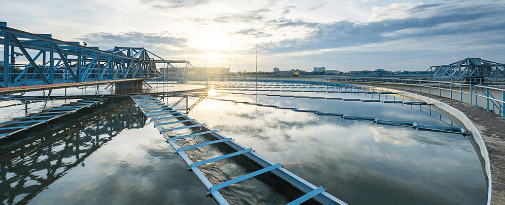

Effective primary waste water treatment is critical to your plant operations, whether discharging directly to a municipal wastewater treatment system or treating prior to your own biological wastewater treatment system. Effective secondary wastewater treatment is important, whether discharging to a publicly owned treatment works (POTW) or to a river. Optimizing the performance of treatment chemicals and equipment can significantly minimize overall costs and maximize the ROI.

Our programs typically focus on the following and can help you with:

- NALMET® — Precipitate metals at low levels with a portfolio of polymers designed for metals management

- 3D TRASAR™ Technology for Dissolved Air Flotation — Visibility and control of solid-liquid separation systems in real time

- FLOCMASTER™ Technology — Optimize dewatering operations and improve sludge management with integration of chemicals, equipment and service

- Full portfolio of polymers to deliver the best system performance and operating requirements

Handling

Material Handling

close

Nalco Water offers several dust control and freeze prevention programs that meet both environmental compliance and employee safety goals. We provide a complete portfolio of products from foaming agents to pile sealants and road dust treatments.

- Sinter Plant — Gas treatment to prevent corrosion, freeze conditioning of raw materials, dust suppression for end products

- Coke Plant — Dust and freeze control for influent and effluent materials, road dust treatments for haul roads

- Blast Furnace — Gas treatment to prevent corrosion, increase reliability of downstream operations

Message

closeThis experience is best viewed on a desktop or tablet browser